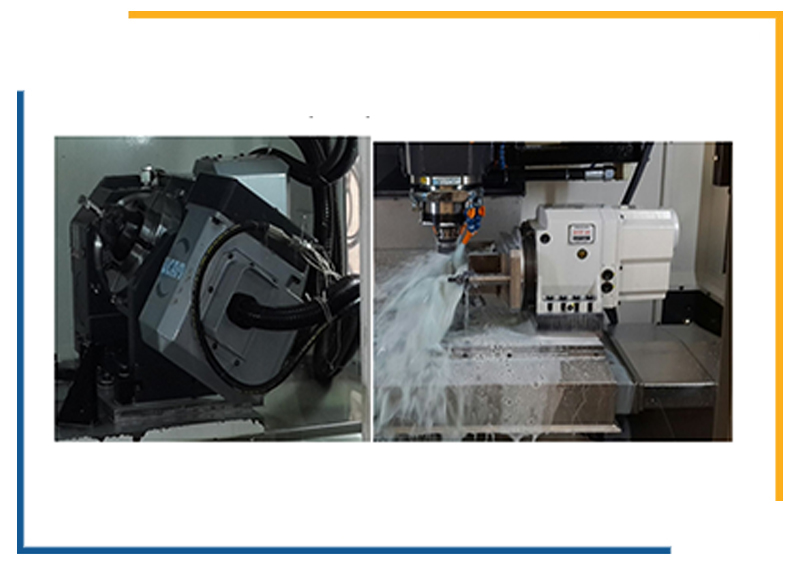

Core competence of our facility and team is in small batch size precision components with prime focus on Customer satisfaction through manufacturing of high quality components with timely delivery at competitive price We do this by using advance CNC machines sourced from best machine tool supplier.

The components are machined as per specification mentioned in the drawing provided by the customer. With help of the vast experience of our staff and team over the years we understand and execute the customer requirement to their complete satisfaction.

Our organization comprises of Engineers to skilled & trained workmen. We follow a very systematic approach. We study, monitoring and evaluate all activities from ‘inward’ up to ‘dispatch’ of goods. We ensure that the overall process for machining of various component manufactured using these machine are well under control and capable.

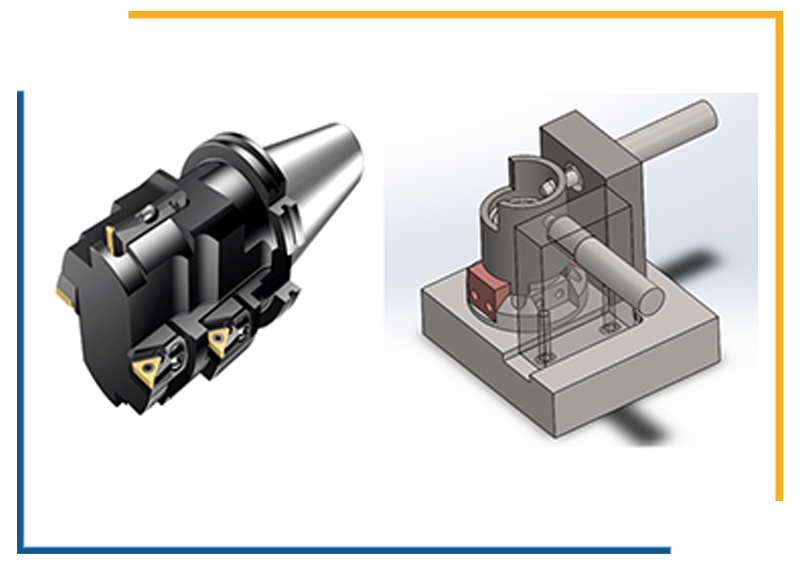

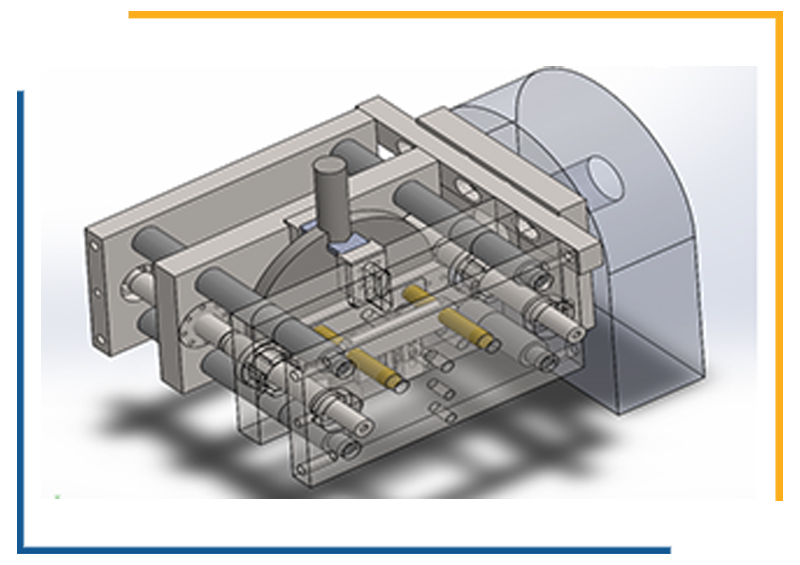

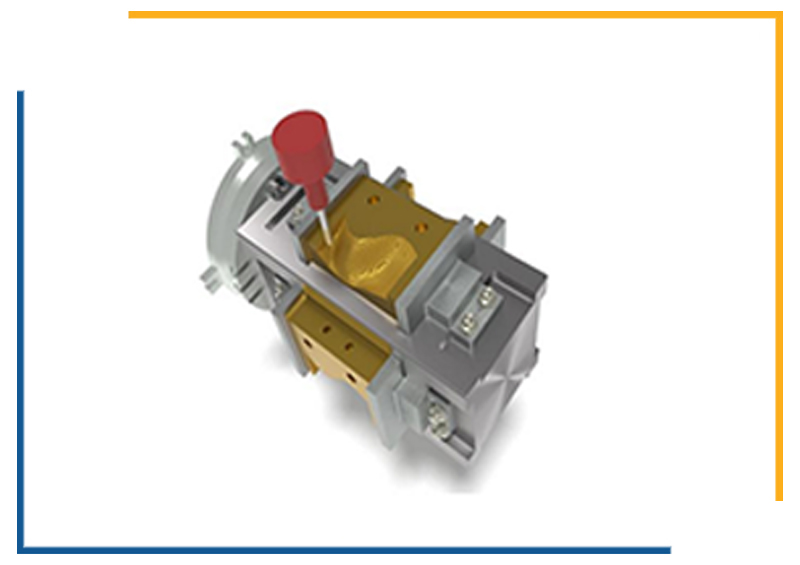

Strong team having experience of more than 20 years in field, with in depth concept of manufacturing engineering, various machining and alied procesess strong, process engineering, fixture and tool design and selection execution experience.

Diversified product range catering to variety of engineering industry segments.

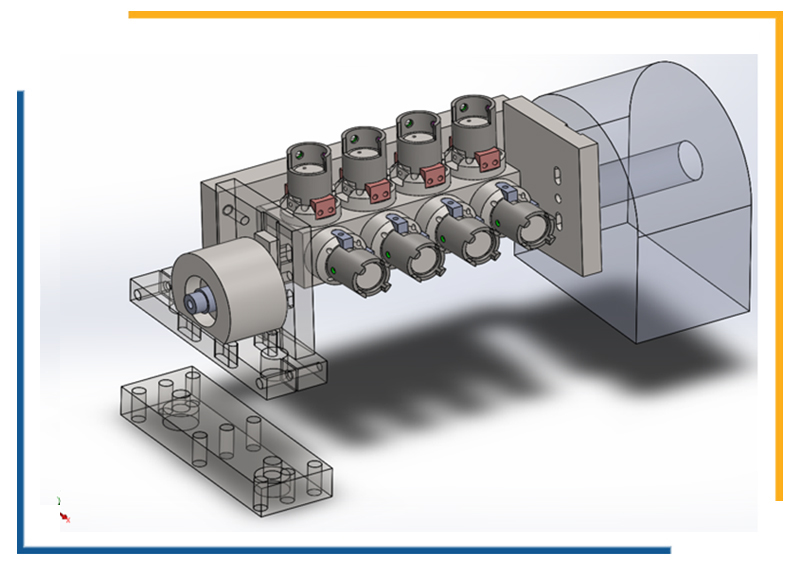

Advanced CAD CAM facility for fool proof planning and execution.

We have a tie-up with best heat treatment facilities for Nitriding, Carburizing, Vaccum Hardening and Induction hardening.

These partners have a very advance heat treatment set up with latest technology. They also have quality measuring instrument to control and check the validity of the process and hence the parts produce.

| SR.NO. | DESCRIPTION | MAKE | QTY |

|---|---|---|---|

| 1 | CNC TURNING CENTER (Lathe) | ACE DESIGNERS Ltd | 2 |

| 2 | CNC TURNING CENTER (Lathe) | PRIDE ULTRA LYNX | 1 |

| 3 | CNC TURNING CENTER (Lathe) | PRIDE JAGUAR | 1 |

| 4 | CNC TURNING CENTER (Lathe) | ACE DESIGNERS Ltd | 1 |

| 5 | VERTICAL MACHINING CENTER | JYOTI MAKE PX 20 | 1 |

| 6 | VERTICAL MACHINING CENTER | COSMOS MAKE CVM640 | 2 |

| 7 | VERTICAL MACHINING CENTER | AMS MAKE SUPER WINNER | 2 |

| 8 | VERTICAL MACHINING CENTER | AMS MAKE MCV-400 | 1 |

| 9 | VERTICAL MACHINING CENTER | AMS MAKE SUPER WINNER | 1 |

| 10 | MEASURING INSTRUMENTS | MITUTOYO | 1 |

| 11 | SURFACE FINISH TESTER SJ-200 | MITUTOYO | 1 |

| 12 | CNC TILTING TABLE FOURTH AXIS | UCAM PRAGATI | 7 |

| 13 | UNIVERSAL TAPPING MACHINE | UNITY | 1 |

| 14 | CAD/CAM SOFTWARE | EDGECAM - VERO | 1 |

With the vision to achieve consistent quality serve we have invested in quality Machines, Measuring Equipment and Tooling. We maintain our measuring equipment by scheduled calibration from NABL certified labs. We also take all efforts to maintain these measuring instruments in good condition.

We have a dust free Inspection Room with temperature control. This room has 2D Height master Mitutoyo make, zero grade surface plate, Surface finish tester and other measuring equipment like Micrometer, Bore gauge, Three point micrometer etc. all of Mitutoyo make.

We also have Thread Plug Gauges, Ring thread gauge, Plug gauges and Master ring gauges as per the requirement. The inspection team maintains the record of First pieces inspection, Production report and history of the parts we machine.

We do 100% inspection of all critical parameter and provide PDI (Pre Dispatch Inspection) to customer. We take all steps to maintain the confidentiality of the customer drawing. We also strictly adhere to NDA( Non Disclosure Agreement), MOU ( Memorandum of Understanding) and other agreement signed with our customer.

We stricktly follow ISO:9001:2015 systems at all levels.

We deliver parts as per the promised delivery date finalize during the acceptance of purchase order. In case of any difficulty we do intimate the customer well in advance. We maintain regular contact with our customer through email, mobile. Care during Packing and transport is very important aspect of delivery.

We take every measure to prevent damage during transit. Every component before dispatch is very well deburred, thoroughly cleaned and then packed with rust preventive oil like VCI412.

We use Polythene bags, Netted sleeve, Corrugated box, Rust preventative paper, Bubble paper, Euro plate, Wooden Box etc. as per customer requirement. We also transport goods by all means Road, Sea and Air as per customer requirement.

We plan our all activities to meet customer delivery dates & monitor on regular intervals.